All About Rotary Screw Air Compressors

Rotary screw air compressors are a staple in many industrial applications, known for their efficiency, reliability, and versatility. Whether you're running a manufacturing plant, an auto repair shop, or any operation requiring a continuous supply of compressed air, understanding the ins and outs of rotary screw compressors is essential. In this blog post, we'll explore how they work, delve into the differences between fixed speed and variable speed compressors, and discuss various use cases to help you decide which type of rotary screw compressor is right for you.

Rotary Screw Compressors Versus Reciprocating Compressors

Rotary screw compressors offer several advantages over reciprocating compressors, making them preferred in many industrial and commercial applications:

Continuous Operation and Efficiency: Rotary screw compressors operate continuously without the pulsating air delivery characteristic of reciprocating compressors. This results in smoother, more consistent airflow and pressure. They are designed for high-duty cycles, making them more efficient in applications requiring a constant supply of compressed air.

Lower Noise Levels: Rotary screw compressors typically produce lower noise levels compared to reciprocating compressors. This is due to their smoother operation and fewer moving parts, which results in quieter performance. Lower noise levels contribute to a more comfortable working environment and may reduce the need for additional soundproofing measures.

Maintenance Requirements: Maintaining rotary screw compressors is often simpler and less frequent than reciprocating compressors. They have fewer wearing parts and operate at lower temperatures, reducing the likelihood of breakdowns and the need for frequent maintenance. Reciprocating compressors, with their piston and valve mechanisms, require more regular inspections and part replacements.

Energy Efficiency: Rotary screw compressors are generally more energy-efficient than reciprocating compressors, especially when considering larger industrial applications. Their continuous operation at variable speeds (in variable speed models) allows them to adjust power consumption to match demand, minimizing energy wastage compared to reciprocating compressors that operate at fixed speeds.

Compact Design and Installation Flexibility: Rotary screw compressors are often more compact and can be installed in smaller spaces compared to reciprocating compressors of similar capacity. This makes them suitable for installations where space is limited or where mobility is required (e.g., portable compressor units). Their compact design also simplifies integration into existing industrial setups.

Suitability for High-Volume Applications: In applications requiring higher volumes of compressed air over extended periods, rotary screw compressors excel. They are capable of delivering consistent air pressure and volume without the need for frequent starts and stops, which can strain reciprocating compressors and reduce their efficiency over time.

In summary, while reciprocating compressors have their own advantages, such as lower initial cost for smaller applications and simpler maintenance routines, rotary screw compressors are generally preferred for their reliability, efficiency, quieter operation, and suitability for continuous, high-volume air compression needs in industrial settings

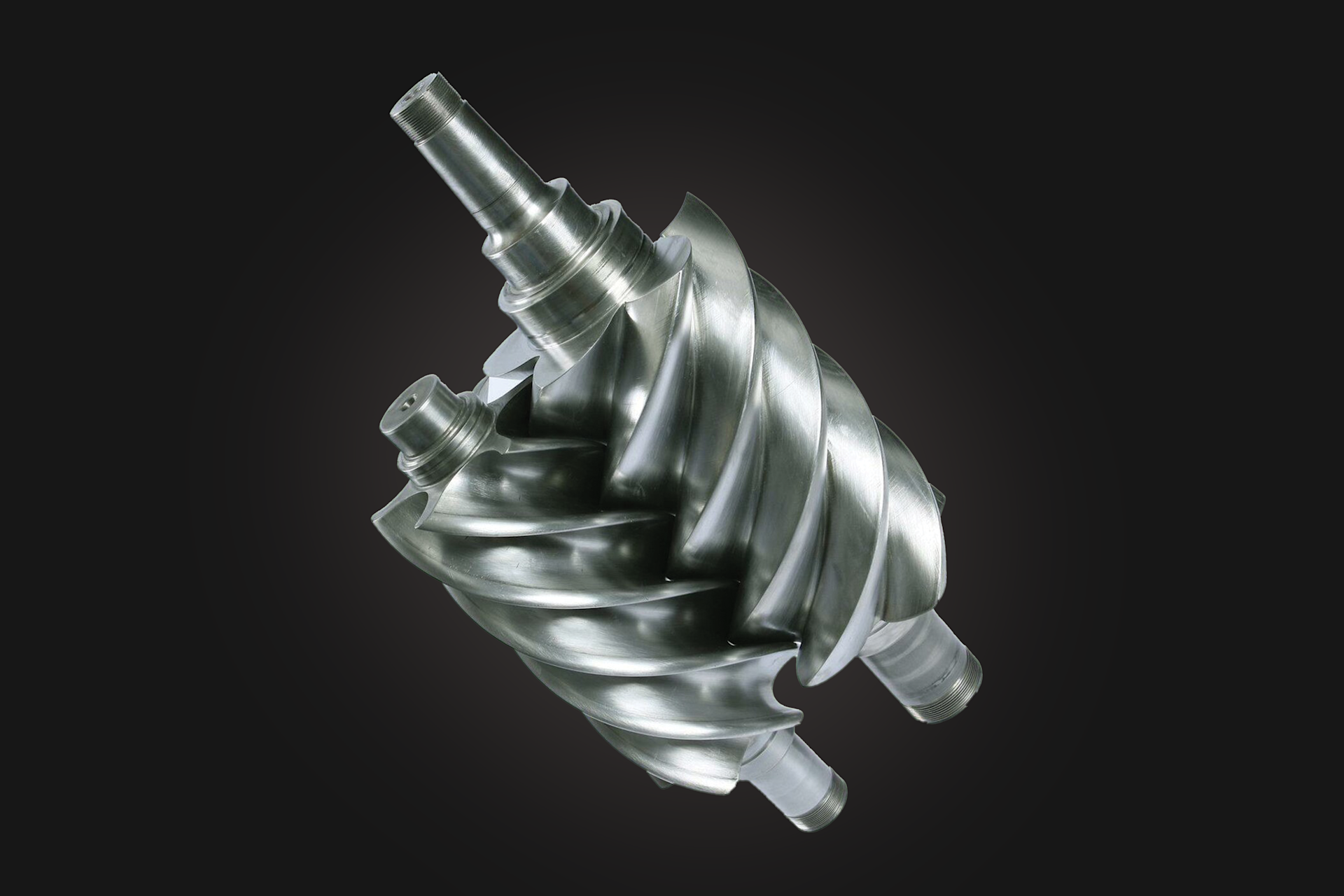

How Rotary Screw Air Compressors Work

At the heart of a rotary screw air compressor are two helical screws (or rotors) that rotate in opposite directions. As these rotors spin, they trap air between them, reducing its volume and increasing its pressure. This process is continuous, providing a steady and efficient supply of compressed air.

Here’s a step-by-step breakdown of the process:

1. Air Intake: Air is drawn into the compressor through an intake valve.

2. Compression: The air is trapped between the two rotating screws. As the screws turn, the space between them decreases, compressing the air.

3. Cooling: The compression generates heat, so the air is cooled, often with a built-in cooling system, to prevent overheating and ensure efficiency.

4. Separation and Filtration: Oil is injected to lubricate, seal, and cool the screws. After compression, the oil is separated from the compressed air and filtered out.

5. Delivery: The compressed air is stored in a tank or delivered directly to the point of use.

Fixed Speed vs. Variable Speed Compressors

Another critical distinction in rotary screw compressors is between fixed speed and variable speed models.

Fixed Speed Compressors

Advantages:

- Simplicity: Easier to operate and maintain with fewer components.

- Lower Initial Cost: Generally cheaper to purchase.

Disadvantages:

- Energy Efficiency: Operates at a constant speed, regardless of demand, which can lead to wasted energy and higher operating costs.

- Wear and Tear: Continuous operation at full speed can lead to increased wear and tear.

Variable Speed Compressors

Advantages:

- Energy Efficiency: Adjusts the speed of the motor to match the air demand, reducing energy consumption and costs.

- Longevity: Reduced wear and tear due to lower operating speeds when full capacity is not needed.

- Flexibility: Better suited for applications with varying air demands.

Disadvantages:

- Initial Cost: More expensive to purchase and potentially to maintain due to more complex components.

- Complexity: Requires more sophisticated controls and maintenance.

Conclusion

Rotary screw air compressors are a versatile and efficient solution for a wide range of industrial applications. Understanding the differences between oiled and oil-free, fixed speed and variable speed models can help you choose the right compressor for your needs. Whether you need a reliable compressor for continuous operation or high-quality oil-free air for sensitive processes, there's a rotary screw compressor that's perfect for your application.