0 | $15,000 | 235 |

|---|---|---|

Vehicle Engine Idle Time To Run A Twister | Saved Annually In Fuel Costs | Maximum CFM and PSI |

Twister In Numbers

Over a decade of research, development, and rigorous testing in extreme environments, has enabled Airworks Compressors Corp to create a mobile truck mounted diesel-powered air compressor unparalleled in today’s market. From its extensive applications, compact size, cost savings and high performance, our diesel powered air compressors are designed to meet all of your mobile air needs. Airworks is the industry leader in clean technology for service truck applications.

Patents & Innovation

The World's First Compact Diesel Powered Air Compressor

Our Twister series was originally created with the goal of minimizing the service truck's engine idle time that was required to run a compressor. By equipping the Twister with its own motor (powered by anything from propane, diesel, gasoline, or even electricity, and more), it could run the compressor while providing power to the truck for systems such as air conditioning.

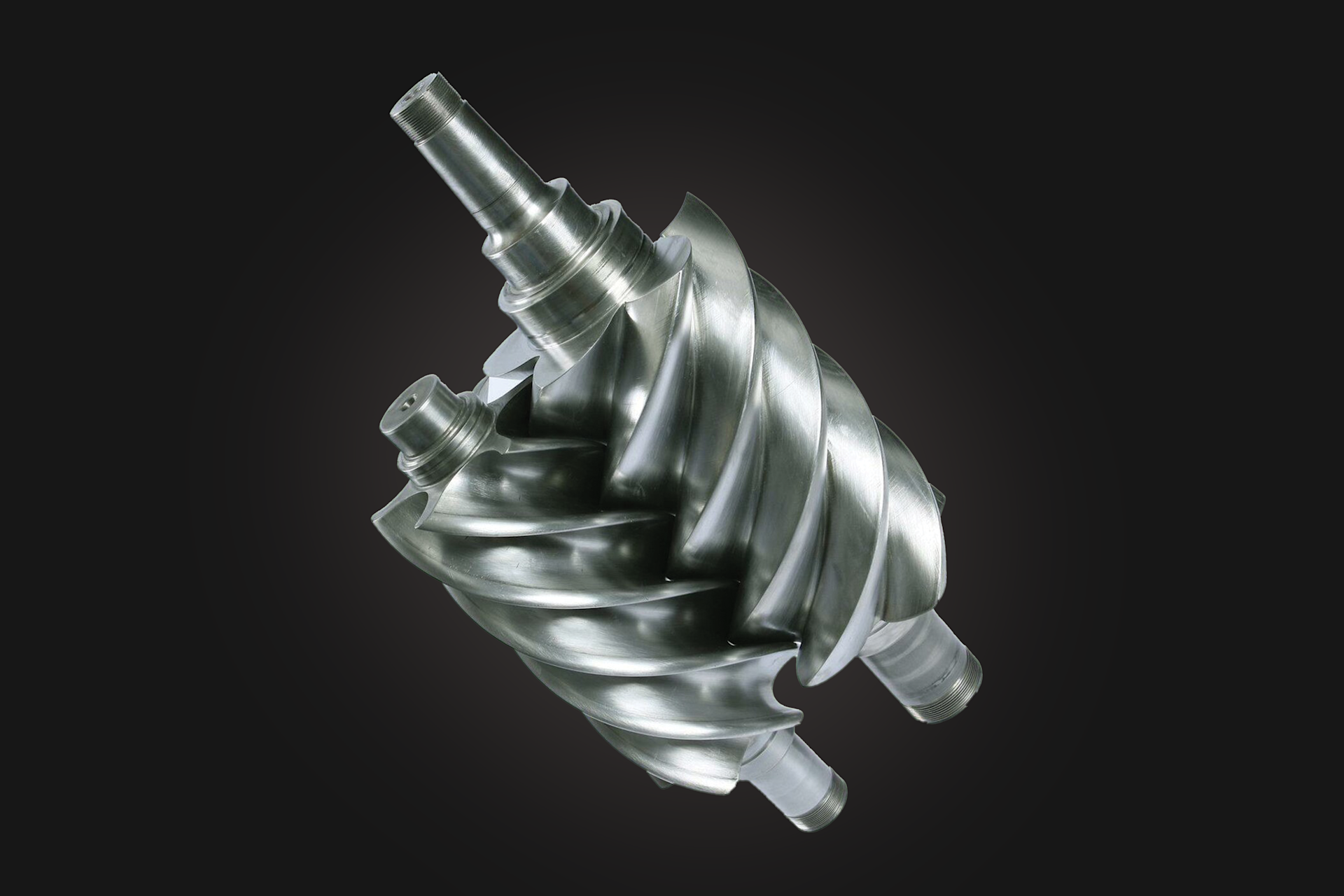

Rotary Screw Air End

Rather than compressing air with pistons, rotary screw compressors draw air between two rotating screws. With this simple configuration, rotary screw compressors are very durable and enjoy very easy maintenance. This technology is comfortable in extreme weather conditions, and can provide massive quantities of airflow for many, many years to come.

Patent US20090162218A1 Combination Power Plant/Fluid Compressor for Service Vehicles

A combination power plant/fluid compressor is provided for service vehicles. A small displacement internal combustion engine can be used to drive a fluid compressor, both mounted on a platform that can be mounted on the vehicle. A coupler is used to directly couple power from a pulley mounted on the crankshaft of the engine to the fluid compressor. The engine can operate on fuel from the fuel tank on the vehicle. The engine can be water-cooled and be configured to circulate heated coolant to the engine cooling system on the vehicle. In another embodiment, the engine can be operatively coupled to a stand-alone air conditioning system. In a further embodiment, the engine can be operatively coupled to a stand-alone electrical charging system.

Read About Our Other InnovationsIndustries

Mining

In the Mining Industry: Air compressors power pneumatic tools essential for mining, such as drills, hammers, and rock-breaking tools. With continuous airflow at high CFM and PSI, they keep critical operations running efficiently in tough environments.

Learn About Other Offerings For This IndustryService Trucks

Our Twister series of air compressors feature a combustion engine or DC motor, paired with a rotary screw compressor contained within the same housing. This lets you run your Twister without ever having to idle your service truck, mitigating unnecessary emissions, reducing fuel costs, and dramatically extending the lifespan of your service vehicle.

Learn About Other Offerings For This Industry