Where is Compressed Air Used?

Compressed air quietly powers essential functions that drive both leisure and industrial sectors. From the precision of manufacturing processes to the reliability in heavy industries like mining and natural gas production, its impact is foundational. This versatile technology not only supports operational efficiency but also plays a pivotal role in advancing sustainability goals across diverse sectors.

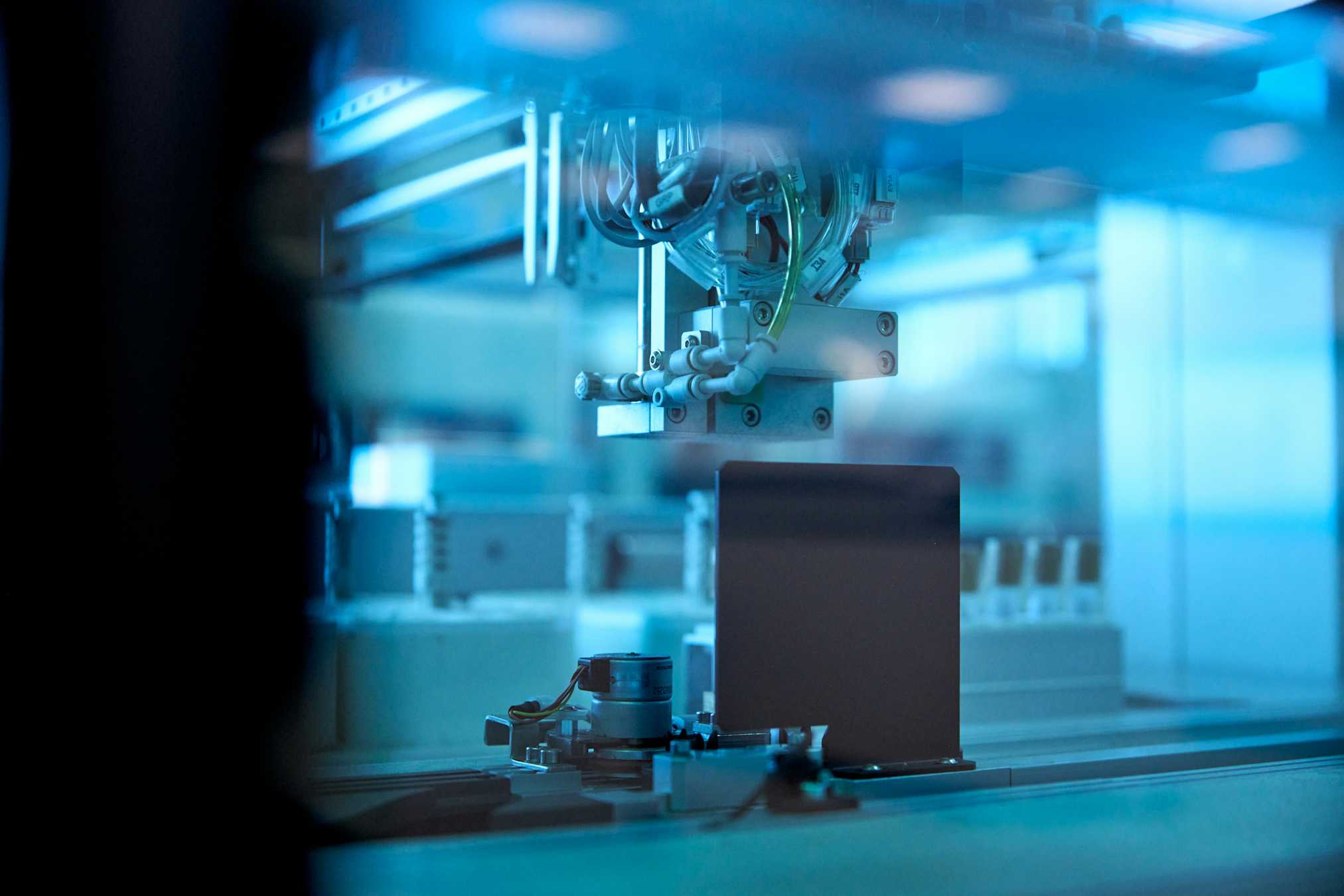

Manufacturing and Industrial Machinery:

Compressed air is indispensable in manufacturing and industrial machinery, where it serves as a versatile and reliable energy source for pneumatic tools and equipment. In manufacturing processes, compressed air powers a wide range of tools, from simple drills to complex robotic arms on assembly lines. Its ability to deliver consistent power and precise control enhances productivity and efficiency, allowing for rapid tool changes and adjustments that minimize downtime. The clean operation of compressed air is crucial in industries such as electronics and pharmaceuticals, where maintaining a contaminant-free environment is essential.

Moreover, compressed air finds applications in material handling, powering pneumatic conveyors and actuators that facilitate the movement of raw materials and finished products throughout production facilities. This technology supports automation efforts by enabling the operation of automated guided vehicles (AGVs) and robotic systems, enhancing manufacturing flexibility and scalability. In heavy machinery manufacturing, compressed air is used for welding operations, metal cutting, and surface preparation, contributing to the production of high-quality components with reduced material waste.

Heavy Industries (Mining, Natural Gas, and Oil Production)

Compressed air plays a critical role in heavy industries such as mining, natural gas extraction, and oil production, where it ensures safe and efficient operations in challenging environments. In mining, compressed air powers drilling equipment, pneumatic tools for rock excavation, and ventilation systems essential for maintaining air quality in underground mines. Its reliability in harsh conditions and ability to operate safely in potentially explosive atmospheres make it indispensable for ensuring worker safety and operational continuity.

Similarly, in natural gas and oil production, compressed air is used for well drilling and completion operations, powering pneumatic actuators for valve control and supporting maintenance activities. Offshore platforms rely on compressed air for emergency response systems, equipment maintenance, and operation of critical safety devices. The technology's versatility extends to pipeline operations, where it facilitates the inspection and maintenance of infrastructure, ensuring the integrity and efficiency of energy transport networks. Compressed air compressors optimized for energy efficiency help reduce operational costs and environmental impact, aligning with sustainability goals in the energy sector.

Food and Beverage Industry

Compressed air is essential in the food and beverage industry, where it ensures hygiene, efficiency, and compliance with stringent food safety standards. In food processing facilities, compressed air powers pneumatic conveyors that transport raw ingredients and finished products without contamination risks, maintaining product integrity throughout the production process. Its use in packaging operations enhances efficiency by driving filling machines, cappers, and labeling equipment with precision and consistency, ensuring accurate packaging and extended shelf life for perishable goods.

Moreover, compressed air supports sanitation efforts in food processing plants, where it operates in washdown environments to clean equipment and production areas effectively. The technology's ability to operate reliably in humid or wet conditions without compromising performance makes it suitable for maintaining high cleanliness levels required in food handling and packaging. Additionally, compressed air is used for pneumatic tools and equipment maintenance, reducing downtime and optimizing operational uptime in food processing facilities. Its role in automation and control systems enhances production efficiency and responsiveness to market demands, contributing to the competitiveness of food and beverage manufacturers.

Chemical Processing

In chemical processing industries, compressed air serves as a versatile utility that supports a wide range of applications, from pneumatic control systems to process automation and equipment operation. Compressed air provides the necessary power for pneumatic pumps, valves, and actuators used in chemical handling and processing. Its ability to deliver precise and consistent pressure control enhances the accuracy of mixing, blending, and dispensing operations, ensuring product quality and uniformity in chemical production.

Moreover, compressed air plays a crucial role in material handling and conveying systems within chemical plants, facilitating the movement of raw materials and finished products throughout production facilities. Its clean and oil-free operation makes it suitable for applications where product purity and contamination control are critical considerations. Compressed air compressors equipped with energy-efficient technologies help reduce operational costs and environmental impact, supporting sustainability initiatives in chemical manufacturing. The technology's reliability and safety features contribute to operational continuity and regulatory compliance in handling hazardous chemicals and volatile substances.

Aeration and Agitation (Wastewater Treatment, Aquaculture)

Compressed air is essential in environmental applications such as wastewater treatment and aquaculture, where it supports aeration and agitation systems critical for maintaining water quality and promoting biological processes. In wastewater treatment plants, compressed air is used to aerate treatment tanks and facilitate the breakdown of organic matter by aerobic bacteria. This enhances the efficiency of biological treatment processes and reduces the concentration of pollutants in treated effluent, supporting environmental sustainability and regulatory compliance.

Similarly, in aquaculture operations, compressed air provides aeration for fish and shrimp ponds, maintaining optimal dissolved oxygen levels necessary for aquatic life. Aeration systems powered by compressed air enhance water circulation and nutrient distribution, promoting the growth and health of aquatic species. The technology's ability to operate reliably in wet and corrosive environments makes it suitable for continuous use in aquaculture facilities, supporting sustainable practices and improving yield and profitability for fish farmers.

Electronics Industry

In the electronics manufacturing industry, compressed air plays a crucial role in maintaining cleanroom environments and supporting precision assembly processes. Compressed air is used to power pneumatic tools and equipment that handle delicate electronic components without causing damage or contamination. It drives automated assembly lines and robotic systems, ensuring precise placement and soldering of components in circuit boards and electronic devices.

Moreover, compressed air is essential for controlling static electricity in electronic manufacturing environments, where electrostatic discharge (ESD) can damage sensitive components. The technology's oil-free and dry air capabilities ensure cleanliness and reliability in semiconductor fabrication, microelectronics assembly, and LCD screen production. Compressed air compressors equipped with advanced filtration systems remove contaminants and moisture from the air supply, maintaining the purity and integrity of electronic products. Its role in automation and process control enhances production efficiency and quality assurance, supporting the competitiveness of electronics manufacturers in global markets.

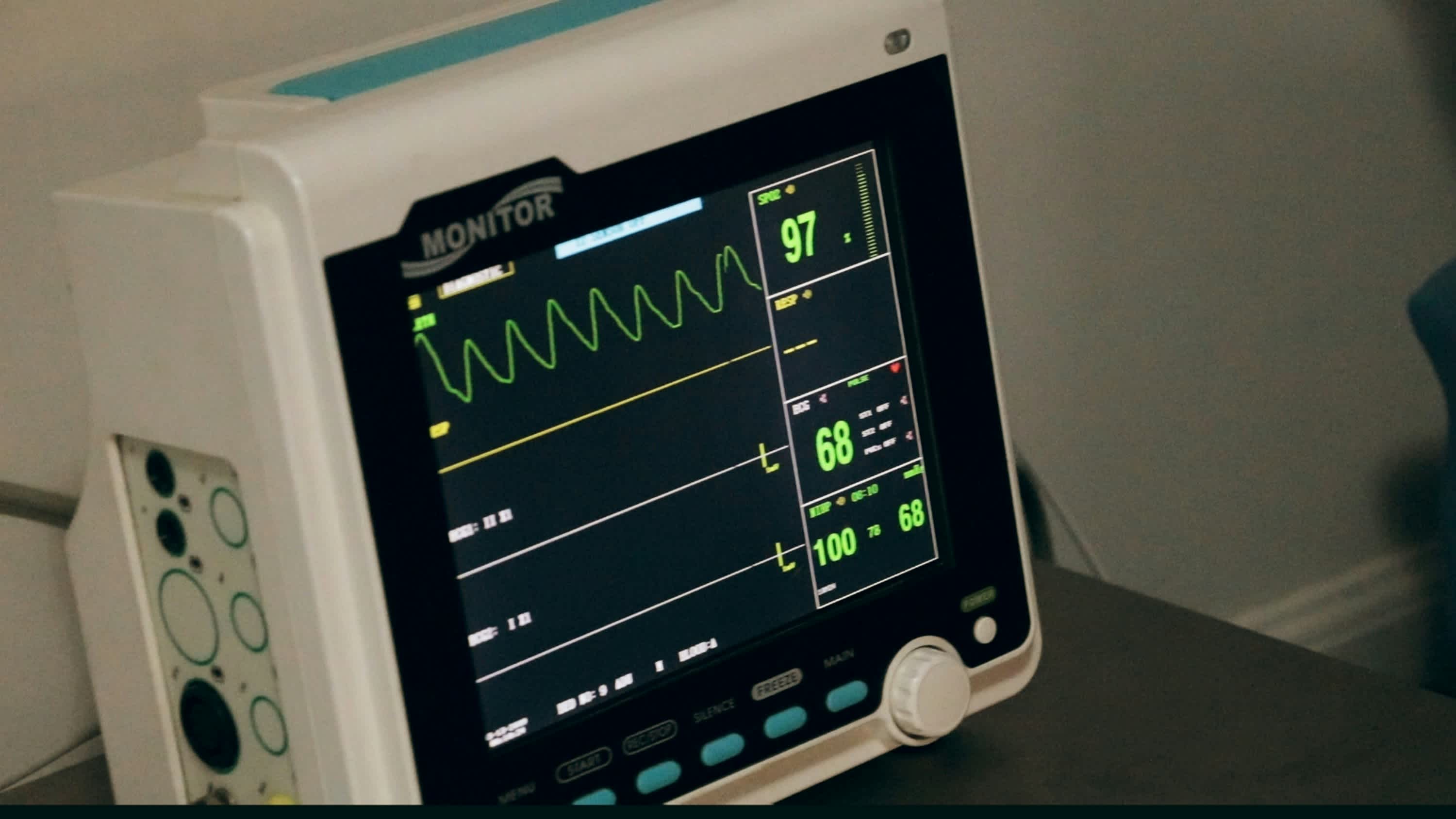

Medical Applications (Breathing Air Systems)

Compressed air is critical in medical applications, providing a safe and reliable source of breathing air for respiratory support equipment used in hospitals, clinics, and emergency response settings. Compressed air systems supply oxygen therapy devices, ventilators, and anesthesia machines with clean and dry air that meets stringent purity standards for patient safety and comfort during medical procedures. The technology's ability to deliver consistent airflow and pressure control ensures effective respiratory support for patients with respiratory conditions or undergoing surgery.

Moreover, compressed air is used in medical air compressors that generate and store compressed air for emergency backup systems and critical care facilities. These systems provide a reliable backup power source during power outages or equipment failures, ensuring uninterrupted patient care and medical treatment. Compressed air compressors equipped with filtration and monitoring systems ensure compliance with healthcare regulations and standards for medical gas systems. The technology's reliability, safety features, and operational efficiency contribute to the quality of healthcare delivery and patient outcomes in medical settings.

Automotive Manufacturing

In the automotive manufacturing industry, compressed air is essential for powering pneumatic tools and equipment used in assembly, painting, and testing processes. Compressed air drives impact wrenches, pneumatic drills, and screwdrivers that streamline assembly line operations and improve production efficiency. Its ability to deliver consistent torque and speed control ensures precision in fastening and assembly tasks, contributing to the quality and reliability of automotive components.

Moreover, compressed air supports pneumatic systems for vehicle painting and coating applications, providing uniform coverage and finish quality. It powers spray guns and automated paint booths that apply primers, basecoats, and clearcoats to vehicle surfaces, enhancing aesthetic appeal and corrosion resistance. The technology's role in automotive testing and quality control includes pneumatic tire inflation systems that measure and adjust tire pressure accurately. Compressed air compressors equipped with energy-efficient motors and variable speed drives optimize energy consumption and reduce operational costs in automotive manufacturing plants. Its versatility and reliability support continuous production cycles and responsive manufacturing capabilities, ensuring competitiveness in the global automotive market.

Energy Production (Power Plants, Renewable Energy)

Compressed air plays a crucial role in energy production, supporting equipment operation and maintenance in power plants and renewable energy facilities. In fossil fuel power plants, compressed air is used for pneumatic actuators that control valves and dampers in steam turbines and boilers. It facilitates the operation of pneumatic tools and equipment for maintenance and repair tasks, ensuring operational reliability and efficiency.

Moreover, compressed air supports renewable energy generation from wind and solar power, where it powers pneumatic systems for turbine blade pitching and solar panel tracking mechanisms. In wind farms, compressed air is used for hydraulic and pneumatic actuators that adjust the angle of wind turbine blades to optimize energy capture from varying wind conditions. The technology's role in energy storage includes compressed air energy storage (CAES) systems that store and release energy during peak demand periods, enhancing grid stability and reliability.

Additionally, compressed air compressors equipped with energy-efficient technologies help reduce carbon emissions and operational costs in power generation facilities. Its reliability and versatility support continuous operation and maintenance activities, contributing to the sustainability and resilience of energy production infrastructure. Compressed air's role in energy efficiency initiatives includes optimizing air compression processes and integrating renewable energy sources into compressed air systems, supporting the transition to a low-carbon energy future.

Sustainable Solutions in Action

Energy Efficiency: Switching to compressed air systems reduces greenhouse gas emissions compared to traditional power sources. This shift not only enhances operational efficiency but also supports global initiatives for sustainable energy practices.

Cost Savings and Compliance: Investing in compressed air technology leads to significant cost savings by minimizing fuel consumption and reducing maintenance costs associated with traditional machinery. Moreover, compliance with stringent environmental regulations becomes more achievable, safeguarding against potential fines and reputational risks.

Future Prospects

Looking ahead, the versatility and reliability of compressed air systems are set to play an increasingly vital role in industrial evolution. As technologies advance, these systems will continue to innovate, driving efficiency gains and environmental sustainability across diverse sectors.

Conclusion

In conclusion, the integration of compressed air technology represents not just a technical upgrade but a strategic commitment to sustainable and efficient industrial practices. By harnessing its power, organizations can achieve operational excellence while contributing positively to environmental stewardship. Embrace the potential of compressed air systems today and pave the way for a greener, more resilient future.